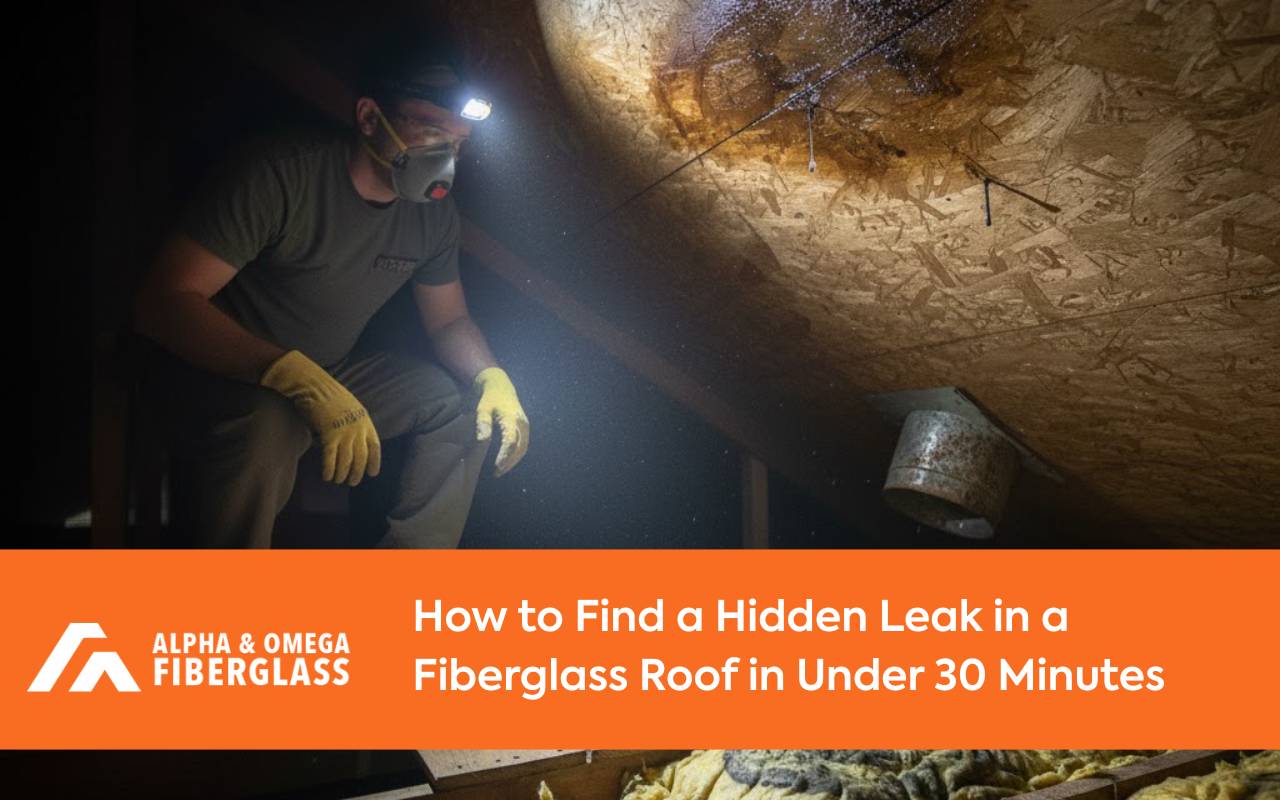

How to Find a Hidden Leak in a Fiberglass Roof in Under 30 Minutes

Leak detection in a fiberglass roof does not have to feel overwhelming or take your entire day. Even a very small leak can slowly create big problems if you ignore it. However, you rarely have time to spend hours searching for the source of the water.

This guide breaks the task into quick, clear steps you can follow in under thirty minutes. You will use simple methods such as probe testing, dye tracing, and infrared basics. Along the way, you will also learn to spot wet insulation signs before they cause serious damage.

Why Finding Hidden Fiberglass Roof Leaks Matters

Early leak detection in fiberglass roofs prevents mold, rotten wood, and damage to insulation and decking. Fiberglass roofs are tough and long-lasting, yet constant sun, wind, and rain slowly create small cracks and weak areas. Over time, those small flaws allow water to sneak into the roof system.

When water stays inside the roof, it can damage lumber, rust fasteners, and create unsafe mold growth. Moreover, moisture can shorten the life of the entire system. Regular checks limit repair costs and protect your home or business. If you prefer a guided approach, review our fiberglass roofing process to see how professionals inspect every layer.

Tools and Equipment Needed for Fast Leak Checks

Before you climb a ladder, gather a few important tools. The right tools make leak detection in fiberglass roofs much faster and far more accurate. You do not need expensive gear, yet you should choose items that are sturdy, safe, and easy to read.

Essential tools for quick inspections

A moisture meter to find damp spots under the surface.

A bright flashlight to reveal hairline cracks and worn seams.

A stable ladder sized correctly for your roof height.

Probe testing tools to feel for soft spots and weak layers.

Fluorescent dye and a UV light for simple dye tracing.

A basic infrared thermometer or small thermal camera for infrared basics.

Protective gloves and safety goggles for personal protection.

Each tool has a clear job. For example, the moisture meter points you toward wet areas, while probe testing confirms soft spots. Dye tracing shows where water travels, and infrared gear highlights temperature changes above wet insulation signs so you can move with confidence.

Initial Inspection: Where to Begin the Search

Start inside the building, not on the roof. Look for obvious wet insulation signs such as dark, sagging, or oddly heavy areas. Also, check the roof deck for rust streaks around nails or screws. These clues show water has already moved past the fiberglass layer and into deeper materials.

Key areas to check first

Attic spaces with visible insulation or open decking.

Ceilings directly under the fiberglass roof panels.

Walls near roof edges and valleys.

Past repair spots that may have failed again.

Next, move onto the exterior roof surface. Walk slowly and follow a safe path. Look for bubbles, blisters, or soft spots in the coating. Pay close attention to skylights, vents, chimneys, and transitions. These details set up more focused tests, saving time during your thirty-minute window.

Using Probe Testing for Precise Leak Identification

Probe testing is a simple, hands-on way to find weakened fiberglass. You press a blunt probe gently into the surface and feel how it responds. A firm area usually means the structure underneath is sound. However, a soft, spongy feel often signals trapped water or damage.

Start by testing the areas you already marked during your visual check. Press lightly at first, then add a bit more pressure. If the probe sinks or fibers start to separate, mark that spot clearly with chalk. This method avoids random poking and narrows your search to the most likely problem zones.

Using Dye Tracing to Confirm the Leak

Dye tracing helps you see how water moves under your fiberglass roof surface. First, choose a non-toxic fluorescent dye designed for leak testing. Mix it with clean water as the label explains. Then gently apply the solution around the area where you suspect a leak.

After a short wait, shine a UV or black light on the surface. The dye shows up as bright lines or small pools, revealing hairline gaps and seam flaws. Because dye tracing follows the same path as water, it offers strong confirmation. Once you locate the exit point, you can plan a focused repair.

Infrared Basics for Fast Roof Leak Detection

Infrared basics are powerful when you want to scan a large roof. Moist areas heat and cool at a different rate than dry areas. A handheld thermal camera or infrared thermometer allows you to see those temperature changes in seconds without opening the system.

Walk the roof in slow, steady lines while watching the display. Cooler or oddly shaped patches may indicate wet insulation signs below the fiberglass. Infrared basics turn leak detection in fiberglass roof into a simple scan instead of a messy teardown. Mark each cool zone so you can compare results with your probe testing and dye tracing.

Reading the Signs of Roof Damage That Need Fast Action

Beyond moisture readings, you should watch for clear signs that demand immediate repair. Blisters or bubbles in the coating can burst and suddenly allow more water inside. Rust spots around metal parts and fasteners mean moisture has stayed in contact with those pieces for a long time.

Common warning signs inside and outside

Ceiling stains or peeling paint under the roof.

Musty or moldy smells in the attic or upper rooms.

Visible mold patches on insulation or framing.

Warped trim, baseboards, or window frames near the roofline.

These symptoms show that water has already moved beyond the surface. When you see several of them together, consider scheduling professional help. Homeowners near New Jersey can review our fiberglass roofing in Cherry Hill, PA, services to understand local options.

Quick and Effective Fixes for Hidden Leaks

Once you know exactly where the leak starts, act right away. For small cracks or pinholes, a fiberglass-compatible roof sealant usually works well. Clean the surface carefully, let it dry, and then apply the sealant as directed. Press and smooth it firmly so it bonds to every edge.

Larger soft or damaged zones may need a fiberglass patch. Cut a patch that extends beyond the weak area. Mix the resin and hardener, then spread a thin, even coat. Place the patch, smooth out bubbles, and allow it to cure. For broad or repeated issues, explore expert fiberglass roof repair services to ensure long-term strength.

Preventive Steps to Avoid Future Fiberglass Roof Leaks

Regular care reduces how often you even need leak detection in fiberglass roof systems at all. Plan simple inspections every few months, especially after harsh storms. During each visit, remove leaves, branches, and other debris so they do not trap standing water on the surface.

Simple habits to protect your roof

Check flashings, vents, and seams for gaps or loose parts.

Touch up sealants and coatings before they peel or crack.

Look for early wet insulation signs in attics or upper rooms.

Keep gutters and downspouts clear so water drains away quickly.

Upgrade problem doorways with professional entry and storm door installation to reduce wind-driven rain at thresholds.

Preventive care costs less than emergency work and keeps your property comfortable and dry. When you combine regular checks with a reliable fiberglass roofing process, you extend the life of your roof and avoid surprise leaks.

Frequently Asked Questions

How long should it take to find a fiberglass roof leak?

With a clear plan and basic tools ready, many homeowners can locate the main problem area in under thirty minutes. Over time, practice makes each step smoother, especially when you pair visual checks, probe testing, dye tracing, and simple infrared basics.

Do I always need special equipment for leak detection?

You can start with very simple tools, such as a flashlight and a ladder. However, moisture meters, dyes, and basic infrared devices help you confirm results. They reduce guesswork and keep you from opening the wrong parts of the roof.

What are the most reliable wet insulation signs?

Look for insulation that looks darker, heavier, or oddly saggy compared to nearby areas. You may also notice musty smells or visible mold, even when surfaces look dry. These clues often appear before ceiling stains show inside your rooms.

When should I call a professional for help?

If you see several warning signs together, or if damage covers a large area, reach out to an expert. You can contact our fiberglass roofing team to discuss repair options, inspection plans, and long-term maintenance support.

Can I walk on my fiberglass roof safely?

Many fiberglass roofs are designed for some foot traffic, yet you should always move with care. Use soft-soled shoes, avoid stepping on weak or blistered zones, and never overload one area. When in doubt, ask a professional to inspect high-risk spots first.

Mastering the Art of Detecting and Fixing Fiberglass Roof Leaks

By following a clear order—visual checks, probe testing, dye tracing, and infrared basics—you can quickly narrow down trouble spots. Combining those methods with careful attention to wet insulation signs ensures you focus on the areas that truly need work.

With practice, leak detection in fiberglass roofs becomes a smooth routine you can finish in under 30 minutes. Consistent preventive care, timely patches, and help from expert fiberglass roof repair services protect your home from hidden water damage and keep your fiberglass roof performing for many years.